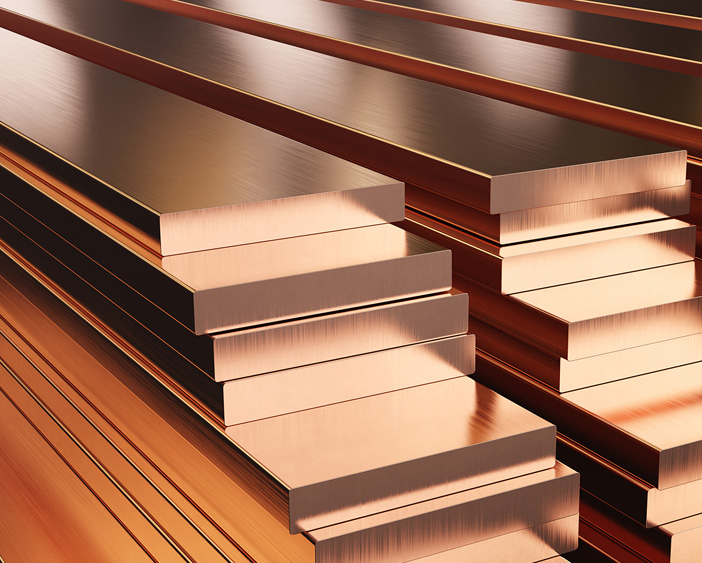

In today’s world, industries are constantly searching for materials and processes that can withstand harsh environments, extend the lifespan of products, and improve overall performance. Among the many protective solutions available, Copper Coating has emerged as one of the most reliable and versatile choices. Its unique properties make it suitable for a wide range of applications, from heavy industry to electronics, and its role in combating corrosion is especially important.

What is Copper Coating?

Copper Coating is the process of applying a thin layer of copper to the surface of another material, usually through methods such as electroplating, thermal spraying, or chemical deposition. This surface treatment not only enhances the appearance of the material but also significantly improves its protective properties.

The Advantages of Copper Coating for Corrosion Resistance

Copper is a naturally durable metal with strong resistance to oxidation and environmental damage. When used as a coating, it creates a barrier that protects underlying materials from rust and degradation. Some of the key benefits include:

• Superior corrosion protection – Copper forms a stable oxide layer that prevents moisture and oxygen from reaching the base material.

• Extended lifespan – By reducing the risk of rust and degradation, Copper Coating ensures that products last longer, reducing the need for frequent replacements.

• Cost savings – Longer service life and reduced maintenance translate into lower long-term costs.

• Enhanced conductivity – Copper is an excellent conductor of electricity and heat, making it ideal for both electrical and mechanical components.

• Versatility – Suitable for steel, aluminum, and even non-metallic materials, depending on the application method.

Industrial Applications of Copper Coating

The growing demand for sustainable and durable solutions has led to the widespread adoption of Copper Coating in multiple industries:

• Construction and infrastructure – Used on steel beams, pipes, and fittings to protect against corrosion in harsh outdoor environments.

• Automotive and aerospace – Ensures critical components remain resistant to wear, oxidation, and extreme temperatures.

• Electronics – Improves conductivity in connectors, printed circuit boards, and sensitive electrical parts.

• Marine industry – Prevents rust and biofouling in equipment exposed to seawater.

• Medical and sanitary equipment – Copper’s natural antimicrobial properties make it valuable for surfaces in hygiene-sensitive environments.

Copper Coating vs. Traditional Protective Methods

While methods such as galvanization or painting are still widely used, Copper Coating provides a stronger and more durable layer of protection. Unlike paint, it doesn’t peel or flake, and compared to zinc or nickel coatings, it offers higher conductivity and better corrosion resistance in specific applications.

Sustainability and the Future of Copper Coating

As industries move toward greener solutions, Copper Coating stands out for its recyclability and long-lasting benefits. By reducing waste, lowering replacement needs, and ensuring components remain operational longer, it contributes to more sustainable manufacturing practices.

The need for advanced corrosion protection has never been greater. Copper Coating offers industries a proven solution that not only enhances durability and performance but also provides cost savings and environmental advantages. Whether in heavy industry, electronics, or medical applications, its role is set to expand in the future.